Insights 22.03.2024

Optimization of Heat Networks and Heating through Artificial Intelligence

Kristina Klehr

Using artificial intelligence, the heating network is then continuously adjusted to the actual needs of the connected users. This means that compared to static or dynamic hydraulic balancing, the PAUL control system automatically and permanently ensures adaptive hydraulic balancing.

Climate goals, heat transition, GEG – The current challenges of the building industry. The steadily increasing energy consumption and harmful CO2 emissions are drivers of climate change, with buildings accounting for over 38% of global emissions. With the goals of the heat transition, the building industry has a clear mandate to reduce these drivers. Within the next 6 years until 2030, greenhouse gases must be reduced by 55%.

The challenges facing the building industry are enormous. Many conventional solutions to reduce energy and CO2 consumption cost a lot of money, time, and additional resources. In addition, there is a need for fair and sustainable tenant policies with socially acceptable rents or operating costs. Meanwhile, energy prices and CO2 taxes continue to rise.

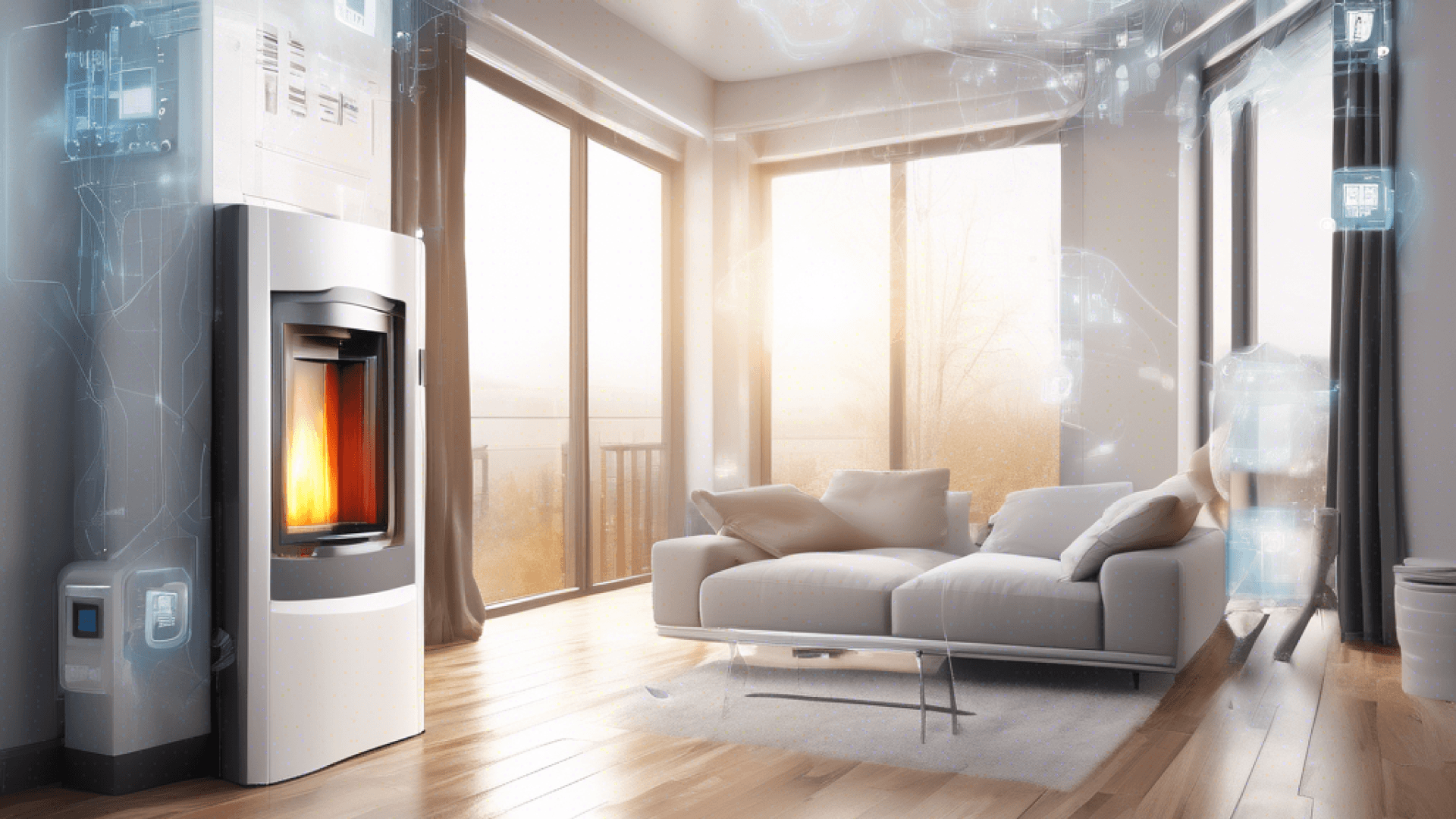

Using digitization of the heat network and artificial intelligence for more energy efficiency. The PAUL Performance control system targets the building’s heat network, optimizes the existing heating system, and digitizes the central building technology by attaching sensors and so-called actuators – motorized valves – to the existing hot water and heating system in the basement. This can be done quickly and minimally invasively without the need to enter the residents’ apartments.

The sensors capture relevant data in real-time. From consumption behavior, location, outside temperature, and technical equipment, a transparent digital profile of the building is created, which can be viewed at any time via PAUL Live, the digital twin of the building. In the dashboard accessible to the customer, the system is visualized 1:1 with all data points displayed, allowing temperatures or temperature trends to be tracked in real-time.

Using artificial intelligence, the heat network is then continuously adjusted to the actual needs of the connected users. This means that compared to static or dynamic hydraulic balancing, the PAUL control system automatically and permanently ensures adaptive hydraulic balancing.

Taking into account the energy-saving effect in hot water heating and heating performance according to their share of the total demand, results in at least 15% energy savings for the entire building. This simultaneously means a reduction in CO2 emissions and an improvement in the energy efficiency class of the building. Without the need for an initial investment, this results in lower energy costs and a reduction in CO2 taxes without sacrificing comfort for the residents. The obligations of the GEG are fulfilled.

From increased energy efficiency in the heat network to the climate neutrality of existing properties. Where the PAUL Performance control system makes an efficient network out of an existing one, the PAUL Net Zero energy platform lays the groundwork for climate neutrality. In principle, anyone already using PAUL Performance can upgrade to PAUL Net Zero.

PAUL Performance makes existing properties “heat pump ready.” This means that anyone considering replacing their existing heating system with fossil energy forms such as oil, gas, and district heating with a heat pump will find an excellent foundation with the PAUL control system.

Immediate effects and future impacts The PAUL control system now offers a solution to the building industry and residents – quickly and cost-neutral. Energy and CO2 savings start from the time of commissioning and immediately contribute to achieving the goals of the heat transition. PAUL is forward-looking and contractually commits to its commitment for at least 10 years. During this time, energy savings are maximized. Additional inventory can be optimized within a year. With the now efficient heat networks in the building, the properties can be equipped with photovoltaics and heat pumps in the next step.